Lamp Industry

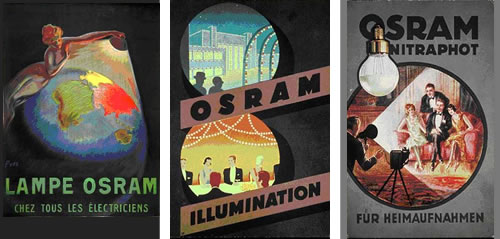

Early 20th century posters for Osram lights

Since the beginning of the 20th century tungsten illuminated the world.

Osmium has the highest optical emission rate of all metals. Consequently, after Edison’s carbon filaments, it was used at the beginning of the lamp industry. Osmium’s big disadvantage is its high vapour pressure, resulting in a short lamp life. Tungsten withstands considerably higher temperatures than osmium and has a very low vapour pressure, resulting in more luminosity combined with a long lifetime.

Tungsten wire possesses characteristics which have provided it with a unique place in the origin and growth of the lamp industry. The lamp industry represents the largest commercial application  of tungsten wire. It is used in this application because it displays excellent creep resistance at elevated temperatures. Tungsten is an attractive lamp filament material because it has an extremely high melting temperature (~3,695 K) and a low vapour pressure at high temperatures. Tungsten is also intrinsically brittle and, initially, this prevented the manufacture of tungsten wire. However, at the beginning of this century William Coolidge, working at the General Electric Company, pursued the idea of deforming tungsten at elevated temperatures in order to make small diameter tungsten wire. Two important findings of his work were, first, to develop a method to work a powder metallurgy ingot down to wire by using deformation at elevated temperatures; and, second, to produce a ductile material from this deformation. Today, the ability to handle tungsten wire and coil filaments without breakage is the backbone of the whole incandescent lamp industry.

of tungsten wire. It is used in this application because it displays excellent creep resistance at elevated temperatures. Tungsten is an attractive lamp filament material because it has an extremely high melting temperature (~3,695 K) and a low vapour pressure at high temperatures. Tungsten is also intrinsically brittle and, initially, this prevented the manufacture of tungsten wire. However, at the beginning of this century William Coolidge, working at the General Electric Company, pursued the idea of deforming tungsten at elevated temperatures in order to make small diameter tungsten wire. Two important findings of his work were, first, to develop a method to work a powder metallurgy ingot down to wire by using deformation at elevated temperatures; and, second, to produce a ductile material from this deformation. Today, the ability to handle tungsten wire and coil filaments without breakage is the backbone of the whole incandescent lamp industry.

The initial stages of thermomechanical processing of sintered tungsten ingot are usually performed by rolling and / or swaging. These operations allow large deformations at relatively high temperatures and, during the initial stages of deformation, the ingot reaches full density. By working the tungsten at elevated temperatures, the tungsten is maintained well above the ductile to brittle transition temperature but below the recrystallization temperature. At various points during this deformation, anneals must be applied, or the tungsten will become overworked and begin to fracture. Finally, wire drawing is used to reduce the tungsten to its final desired diameter. At this point, the microstructure consists of fibres which have very high aspect ratios: they act like fibres in a rope and provide bend ductility.

It was no until the advent of transmission electron microscopy that potassium was located in small bubbles in the tungsten. It is these potassium bubbles which provide the wire with its unique high temperature creep resistance. Potassium is essentially insoluble in the tungsten. The bubbles are first formed from the doped powder in the ingot during sintering. During thermomechanical processing, these initial bubbles are drawn out into tubes. When the wire is annealed, these tubes break up to form the rows of bubbles.

It was no until the advent of transmission electron microscopy that potassium was located in small bubbles in the tungsten. It is these potassium bubbles which provide the wire with its unique high temperature creep resistance. Potassium is essentially insoluble in the tungsten. The bubbles are first formed from the doped powder in the ingot during sintering. During thermomechanical processing, these initial bubbles are drawn out into tubes. When the wire is annealed, these tubes break up to form the rows of bubbles.

Once wire drawing is complete, the tungsten can be coiled into a filament and recrystallized. When the wire is recrystallized, the grain boundaries interact with the potassium bubble rows as the boundaries migrate, giving rise to an interlocking grain structure.

Recrystallized pure tungsten wire forms a bamboo structure: the grains occupy the entire wire diameter, and the boundaries are essentially perpendicular to the wire axis. At elevated temperatures, under the stress produced by gravity, these boundaries would slide past one another by diffusion and produce a rapid failure. However, when potassium is present in the wire, the interlocking grain structure reduces the rate of grain boundary sliding and extends the filament life. These bubbles continue to pin the grain boundaries at the temperatures of lamp operation, and thus maintain a stable microstructure during the life of the lamp.

Tungsten is used in many different types of incandescent lamps. The most common types are the general household lamps, automotive lamps, and reflector lamps for floodlight or projector applications. There are also many thousands of speciality lamps, which have a broad range of applications, such as audio-visual projectors, fibre-optical systems, video camera lights, airport runway markers, photoprinters, medical and scientific instruments, and stage or studio systems.

Tungsten is used in many different types of lamp

The image below, representing permanent lights on the Earth’s surface, was created with data from the Defense Meteorological Satellite Program (DMSP). Even more than 100 years after the invention of the tungsten light bulb, some areas still remain dark. Tungsten is used as lamp filament in ordinary light bulbs and halogen lamps but also in the form of electrodes for discharge lamp systems and arc lamps.

sales@chinatungsten.com

sales@chinatungsten.com